PE Tube

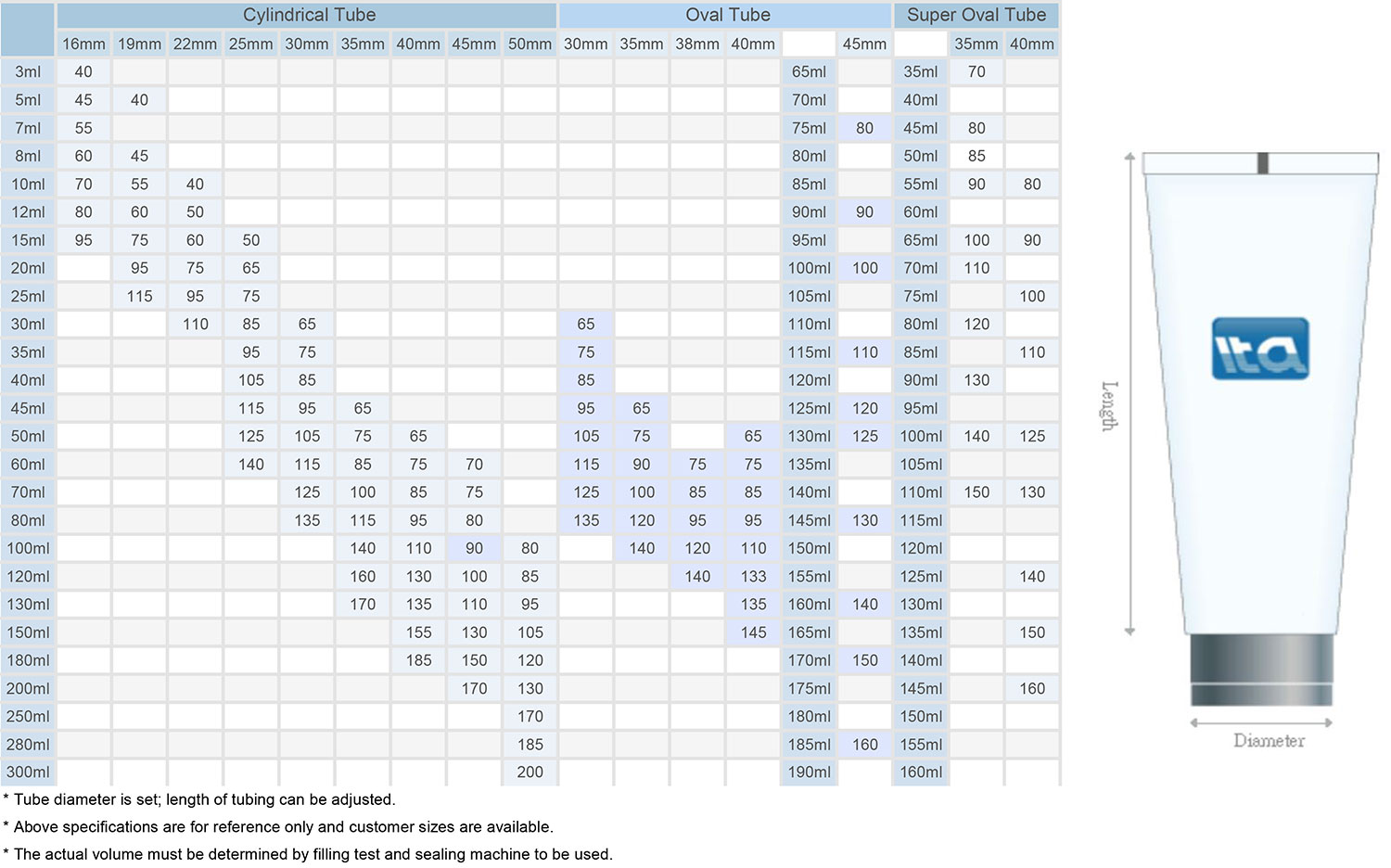

PE extruded tubes is an economical process of making primary cosmetic tube containers. By using extruded machine to melt the PE resins is the most conventional method of manufacturing cosmetic tubes. After molding the tube sleeves, the tube length is decided by cutting machine. In this process, the tube color could be customized to any color you want.

Tube shoulder

After decorating the tube sleeves, it is time to inject the tube shoulder. I. TA uses vertical injection machines to manufacture the tube shoulders. The advantage of using vertical injectors is that we can make cosmetic round tubes, primary oval tubes, or even body care super oval tubes in the same machine. Therefore, the cost of developing a new tube shoulder/head tooling is affordable for customers.

- Related Products

Jagged Screw Cap for burn aid cream tube

D25-250

Dia 25mm flexible plastic tube normally can be applied on cosmetics, skincare product, gel essence, lotion, hand cream or some liquid products.

DetailsStandard Screw Cap for 10ml cosmetic tube

D19-191A

Dia 19mm flexible plastic tube normally can be applied on small capacity cosmetics, skincare product, eye cream, serum, lip cream, essence concentrate,...

DetailsStandard Screw Cap with Flat Applicator for cosmetic tube

D19-191-8090

Dia 19mm flexible plastic tube normally can be applied on small capacity cosmetics, skincare product, eye cream, serum, lip cream, essence concentrate,...

Details